Volvo ART 500G – Articulated Hauler Simulator

The Volvo ART 500 Simulator delivers an authentic training experience with original G-series controls, Volvo Co-Pilot 2.0 with Haul Assist, a high-performance motion platform, and an industrial-grade visualization system. Designed for ease of use and maximum realism, it offers an immersive environment suitable for both new and experienced operators.

With over fifteen training scenarios, the simulator covers the core skills required to operate the Volvo A45 articulated hauler. Each scenario is built around real-world challenges, helping operators build confidence and efficiency in day-to-day operations.

Also Available as an Add-On

The Volvo ART training package is also available as an add-on kit for the Volvo WLO 500G Simulator. The kit includes dedicated ART controls and allows for a quick transition between the two setups—in under a minute—offering unmatched flexibility and value.

What’s included

- Volvo original seat and G-series controls

- 55″ HD Industry grade LCD screen

- High-performance motion platform

- 15 training scenarios and two Expo/demonstration scenarios

- Operator Performance System (OPS)

- Three-year Simulator Support Agreement

- Online, phone & e-mail support with 24h response guarantee*

OPTIONS

- Volvo Co-Pilot 2.0

For more information on Volvo ART 500 and its scenarios, download the product description

Volvo Co-Pilot 2.0

Volvo Co-Pilot 2.0 is an innovative assistance system for heavy equipment operators, now fully integrated into the ART 500 and available as an option for a highly realistic training experience. With advanced features such as Haul Assist with Onboard Weighing and Operator Coaching, operators can practice precision work, load optimization, and efficient material handling in a safe, virtual environment.

By training on the Volvo Co-Pilot 2.0 in the simulator before operating real machinery, operators become safer, more productive, more efficient, and fully prepared to perform at their best from day one.

Multiple Configurations

The ART 500 simulator is available in a range of configurations to suit different training needs and environments—ensuring there’s a solution for everyone:

- Single Screen with Caster Wheels

A highly mobile option, ideal for flexible training spaces. -

Single Screen with Motion Platform (MPF)

A compact setup enhanced with motion feedback for a realistic training experience. - Three Screens with Caster Wheels

Expansive visuals in a portable, easy-to-relocate format. -

Three Screens with Motion Platform (MPF)

An immersive, full-field view combined with motion for advanced simulation realism

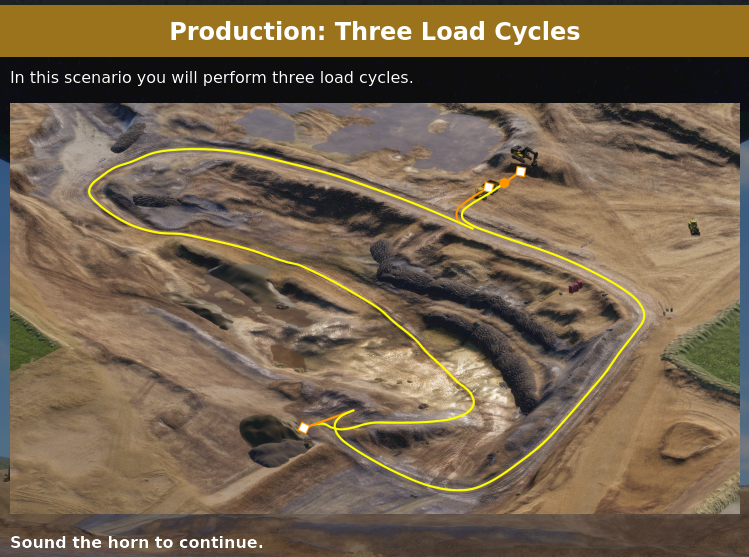

Comprehensive Training

The simulator offers a wide range of training and demonstration scenarios, many of them set within a virtual replica of our Eskilstuna Demo Center. This allows operators to practice in realistic environments and prepare for a variety of real-world situations such as driving uphill, downhill, through muddy conditions, or at night. From foundational skills to complex site operations, each exercise is tracked and evaluated through the integrated Operator Performance System (OPS).

Machine Operations

Build essential skills and develop a deep understanding of machine functionality and controls.

Productivity Training

Start by evaluating your current performance, then progress through guided scenarios designed to improve efficiency and on-site productivity.

Grouped Scenarios

Structured, goal-oriented training modules that streamline learning, boost operator independence, and maximize training outcomes.

For more information on the included scenarios, download the detailed scenario description.

Skill Enhancement

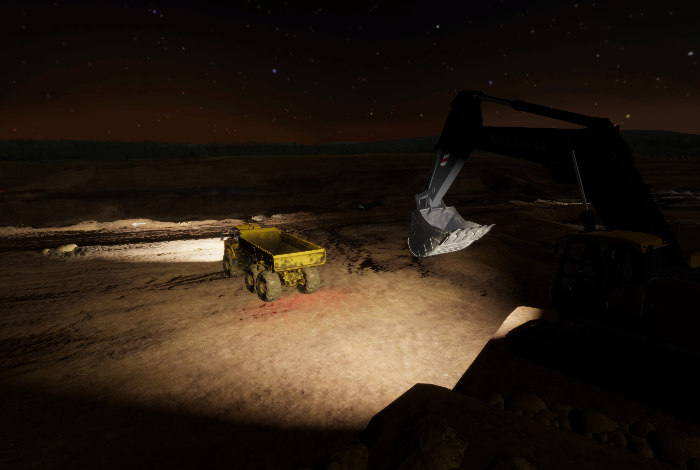

In this scenario example, operators will complete a full production cycle with the Volvo A45 articulated hauler under nighttime conditions. The task begins by reversing into the loading position indicated by the excavator’s bucket. Once properly aligned, the excavator will sound its horn and begin loading—operators must remember to engage the load and dump brake during this process.

After loading, operators will follow ground indicators to the designated dump area and unload the material within the marked zone. Safe operation is critical: maintaining appropriate downhill speeds and using the load and dump brake while dumping are key to successful performance.

Results are evaluated based on production efficiency, operational safety, and fuel economy—mirroring the demands of real-world job sites.

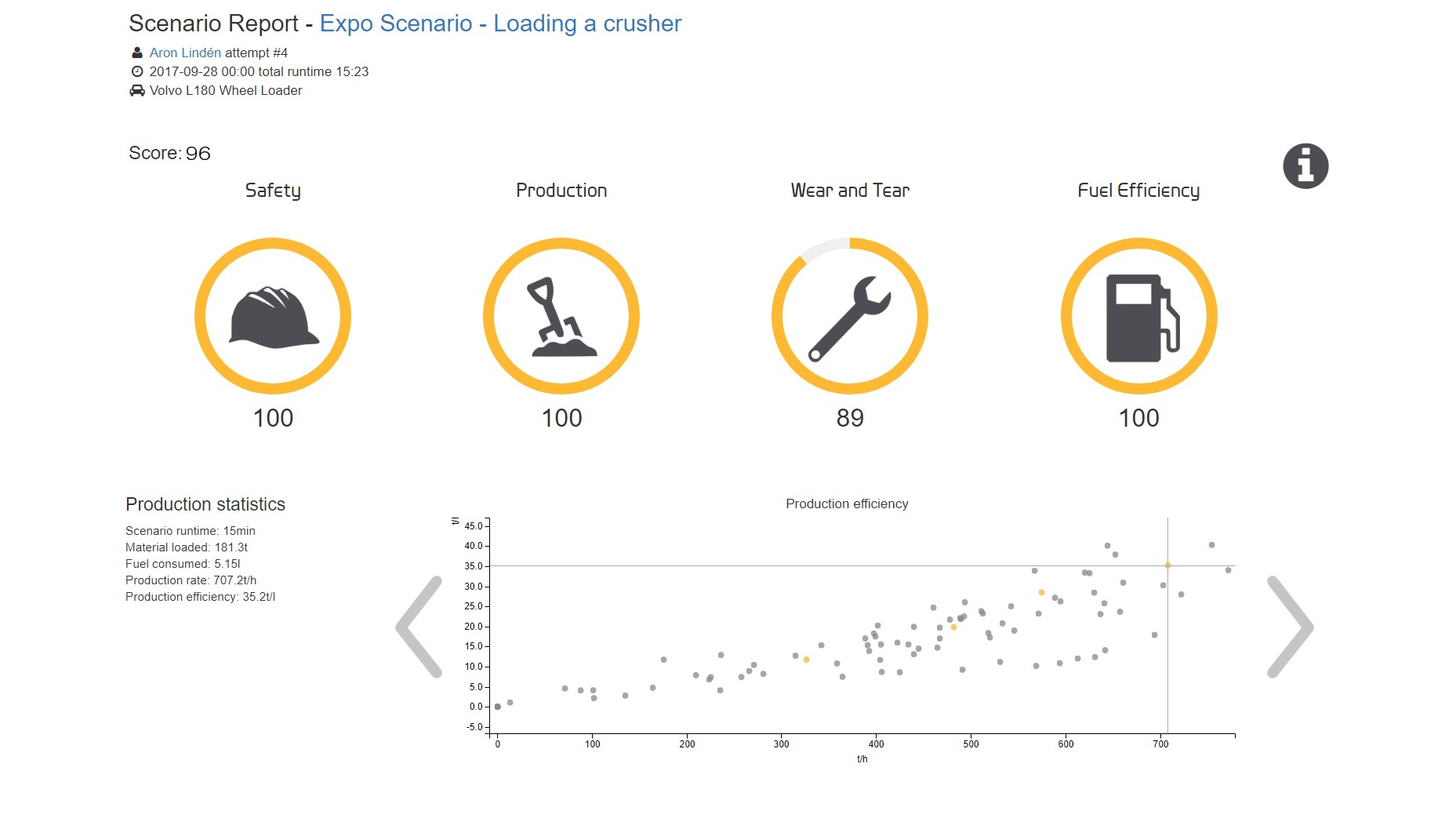

Operator Performance System (OPS)

All Volvo CE simulators come equipped with an integrated user management system that tailors specific training paths for each student. Each scenario generates an Operator Performance System report, providing comprehensive statistics on the operator’s performance. This includes a total score and grading based on predefined criteria.

Following the completion of every scenario, operators receive a detailed performance report highlighting successes and areas for improvement. For instance, while achieving excellent completion time and production scores, the report may uncover issues such as high fuel consumption and unnecessary wear and tear. This capability not only identifies potential concerns difficult to detect with real machinery but also helps in cost mitigation and enhances overall safety.

Articulated Hauler Add-On Kit for WLO 500

Available as an optional upgrade for the WLO 500 simulator, the ART Add-On Kit transforms a Volvo Wheel Loader simulator into a fully functional articulated hauler in under a minute—thanks to its quick-swap control system. It includes the same comprehensive training scenarios featured in the standalone ART 500 simulator, offering seamless versatility without compromising on realism or performance.